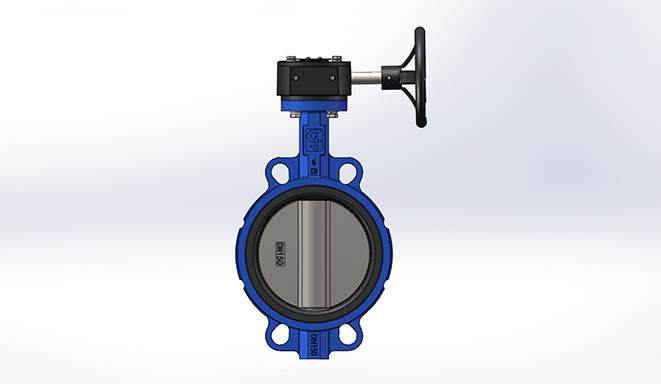

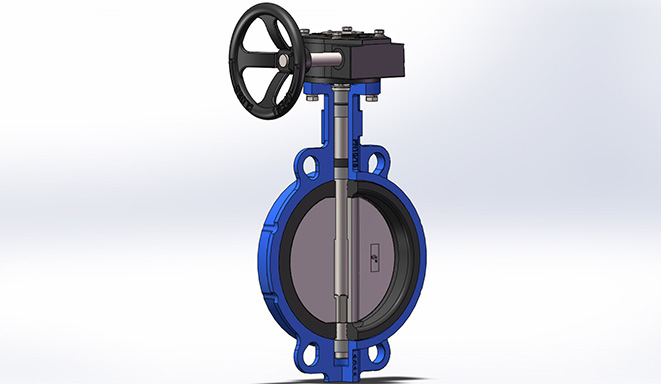

| Design and Manufacture Standard: | API 609 |

| Face to Face:: | API 609 |

| Test Standard: | API 598 |

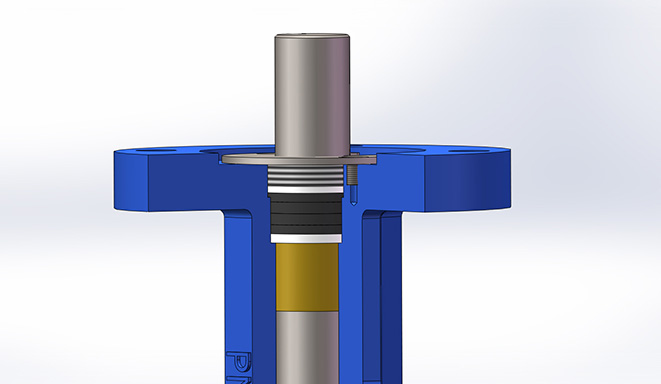

| Top Flange Connection Standard: | ISO 5211 |

| Flange Size Standard: | ASME B16.5、ASME B16.47、DIN 2501 |

| ASME B16.1、JIS B2220 |

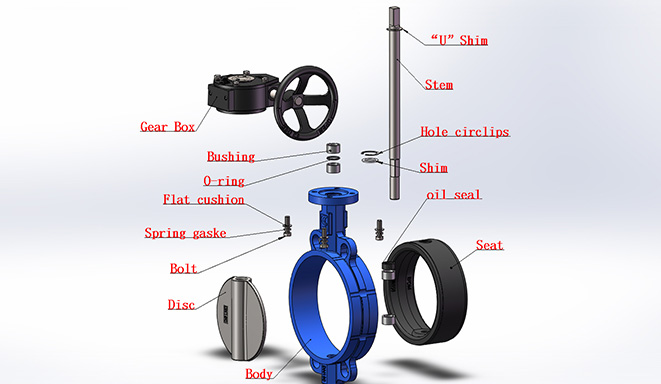

| Body Materials: | DI |

| Disc Materials: | DI、CF8、CF8M、CF3、CF3M、1.4529、C594、C598 |

| Seat Materials: | EPDM、NBR、Viton、PTFE |

| Stem Materials: | SS416、SS420、SS304 |

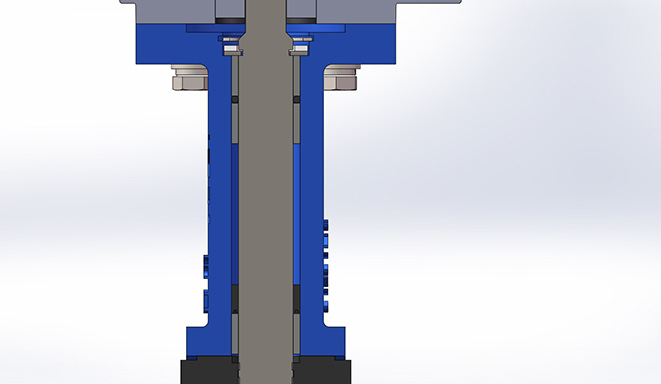

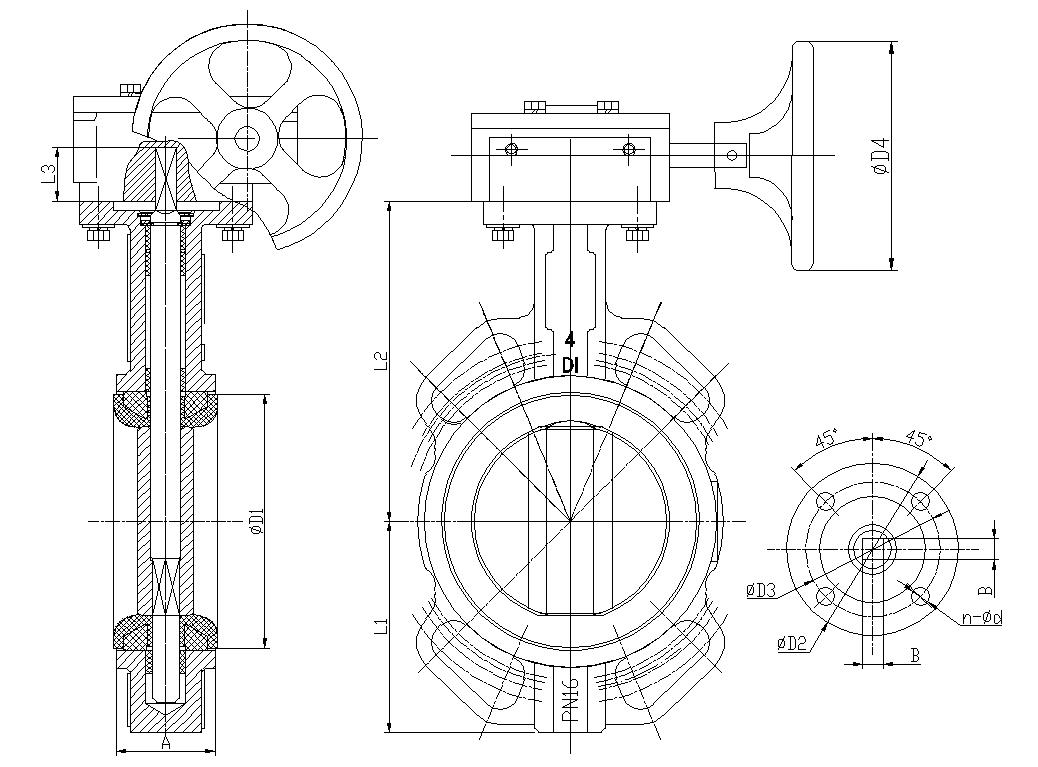

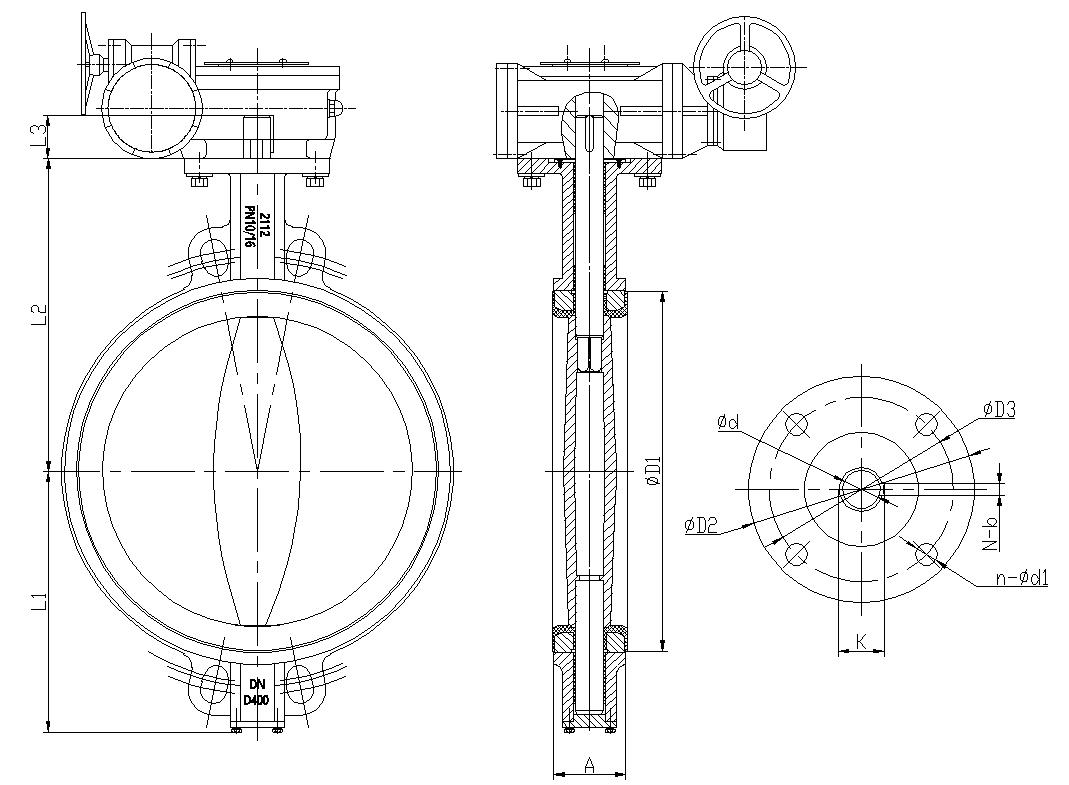

| DN | A | D1 | L1 | L2 | L3 | B | φD2 | φD3 | n-φd | φD4 | |

| 1.5″ | DN40 | 33 | 69 | 65 | 127 | 25 | 9 | 65 | 50 | 4-8 | 135 |

| 2″ | DN50 | 42 | 73.3 | 75 | 129 | 25 | 9 | 65 | 50 | 4-8 | 135 |

| 2.5″ | DN65 | 44 | 86 | 82 | 136 | 25 | 9 | 65 | 50 | 4-8 | 135 |

| 3″ | DN80 | 45 | 100.9 | 99 | 153 | 25 | 9 | 65 | 50 | 4-8 | 135 |

| 4″ | DN100 | 51.5 | 132 | 110 | 167 | 28 | 11 | 90 | 70 | 4-10 | 135 |

| 5″ | DN125 | 54 | 156 | 125 | 193 | 28 | 14 | 90 | 70 | 4-10 | 135 |

| 6″ | DN150 | 55 | 185 | 145 | 209 | 28 | 14 | 90 | 70 | 4-10 | 135 |

| 8″ | DN200 | 59 | 235 | 170 | 251 | 33 | 17 | 125 | 102 | 4-12 | 270 |

| 10″ | DN250 | 66 | 289 | 210 | 280 | 33 | 22 | 125 | 102 | 4-12 | 270 |

| 12″ | DN300 | 76 | 341 | 240 | 312 | 33 | 22 | 125 | 102 | 4-12 | 270 |

| 14″ | DN350 | 76 | 372 | 271 | 327 | 45 | 22 | 125 | 102 | 4-12 | 270 |

| DN | A | D1 | L1 | L2 | L3 | φd | φD2 | φD3 | n-φd1 | N-b | K | |

| 16″ | DN400 | 86.5 | 436 | 320 | 403 | 52 | 33.15 | 175 | 140 | 4-18 | 1-10 | 36.2 |

| 18″ | DN450 | 104.6 | 487 | 351 | 415 | 52 | 38 | 175 | 140 | 4-18 | 1-10 | 41 |

| 20″ | DN500 | 130 | 532 | 386 | 466 | 64 | 41.15 | 175 | 140 | 4-18 | 1-12 | 44.2 |

| 24″ | DN600 | 152 | 651 | 446 | 525 | 70 | 50.65 | 210 | 165 | 4-22 | 1-16 | 54.7 |

| 28″ | DN700 | 163 | 741 | 520 | 618 | 95 | 63.35 | 300 | 254 | 8-18 | 2-18 | 71.4 |

| 32″ | DN800 | 188 | 847 | 580 | 665 | 95 | 63.35 | 300 | 254 | 8-18 | 2-18 | 71.4 |

| 36″ | DN900 | 203 | 971 | 670 | 720 | 130 | 75 | 300 | 254 | 8-18 | 2-20 | 84 |

| 40″ | DN1000 | 216 | 1050 | 735 | 800 | 130 | 85 | 300 | 254 | 8-18 | 2-22 | 95 |

| 48″ | DN1200 | 276 | 1261 | 878 | 940 | 150 | 105 | 350 | 298 | 8-22 | 2-28 | 117 |