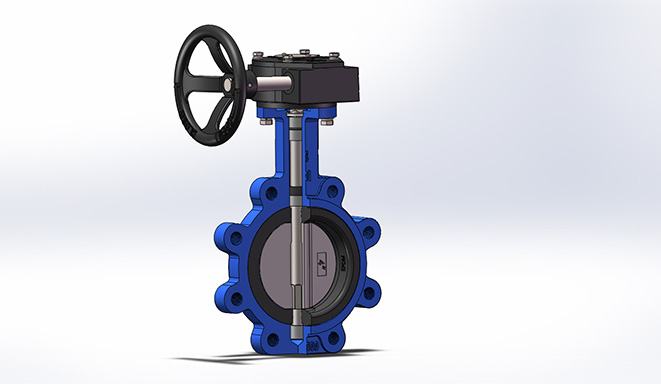

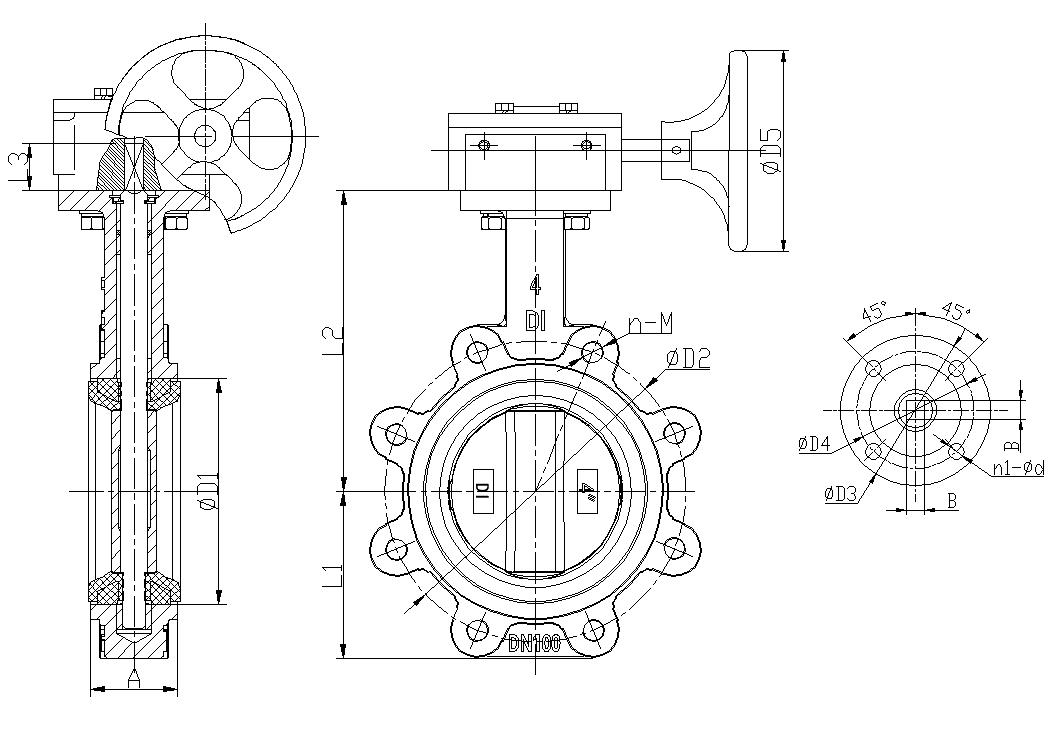

| Design and Manufacture Standard: | API 609 |

| Face to Face | API 609 |

| Test Standard: | API 598 |

| Top Flange Connection Standard: | ISO 5211 |

| Flange Size Standard: | ASME B16.5、ASME B16.47、 |

| ASME B16.1、JIS B2220、DIN 2501 |

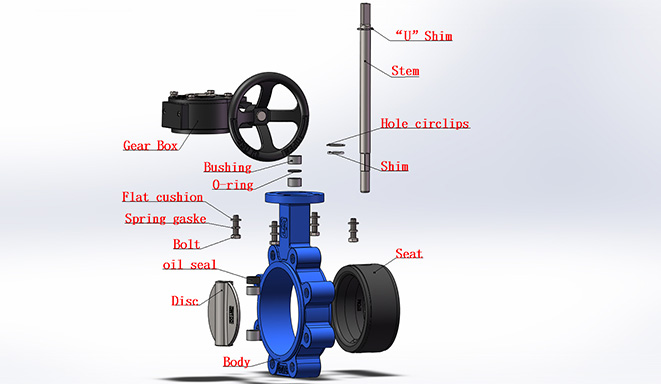

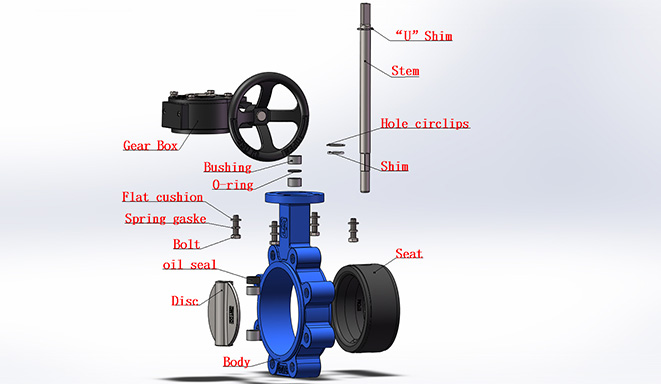

| Body Materials: | DI |

| Disc Materials: | DI、CF8、CF8M、CF3、CF3M、1.4529、C594、C598 |

| Seat Materials: | EPDM、NBR、Viton、PTFE |

| Stem Materials: | 45、SS416、SS420、SS304、SS431 |

| DN | A | D1 | L1 | L2 | L3 | B | PN16 | PN10 | 150LB | φD3 | φD4 | n1-φd | D5 | ||||

| D2 | n-M | D2 | n-M | D2 | n-M | ||||||||||||

| 2″ | DN50 | 42 | 73.3 | 54 | 161 | 25 | 9 | 125 | 4-M16 | 125 | 4-M16 | 120.7 | 4-5/8″ | 65 | 50 |

4-8 |

135 |

| 2.5″ | DN65 | 44 | 86 | 62 | 175 | 25 | 9 | 145 | 4-M16 | 145 | 4-M16 | 139.7 | 4-5/8″ | 65 | 50 |

4-8 |

135 |

| 3″ | DN80 | 45 | 100.9 | 82 | 181 | 25 | 9 | 160 | 8-M16 | 160 | 8-M16 | 152.4 | 4-5/8″ | 65 | 50 |

4-8 |

135 |

| 4″ | DN100 | 51.5 | 132 | 99 | 200 | 28 | 11 | 180 | 8-M16 | 180 | 8-M16 | 190.5 | 8-5/8″ | 90 | 70 |

4-10 |

135 |

| 5″ | DN125 | 54 | 156 | 114 | 213 | 28 | 14 | 210 | 8-M16 | 210 | 8-M16 | 215.9 | 8-3/4″ | 90 | 70 |

4-10 |

135 |

| 6″ | DN150 | 55 | 185 | 129 | 236 | 28 | 14 | 240 | 8-M20 | 240 | 8-M20 | 241.3 | 8-3/4″ | 90 | 70 |

4-10 |

135 |

| 8″ | DN200 | 59 | 235 | 150 | 260 | 33 | 17 | 295 | 12-M20 | 295 | 8-M20 | 298.5 | 8-3/4″ | 125 | 102 |

4-12 |

270 |

| 10″ | DN250 | 66 | 289 | 186 | 292 | 33 | 22 | 355 | 12-M24 | 350 | 12-M20 | 362 | 12-7/8″ | 125 | 102 |

4-12 |

270 |

| 12″ | DN300 | 76 | 341 | 218 | 337 | 33 | 22 | 410 | 12-M24 | 400 | 12-M20 | 431.8 | 12-7/8″ | 125 | 102 |

4-12 |

270 |

| 14″ | DN350 | 76 | 372 | 242 | 368 | 45 | 22 | 470 | 16-M24 | 460 | 16-M20 | 476.3 | 12-1″ | 125 | 102 |

4-12 |

270 |

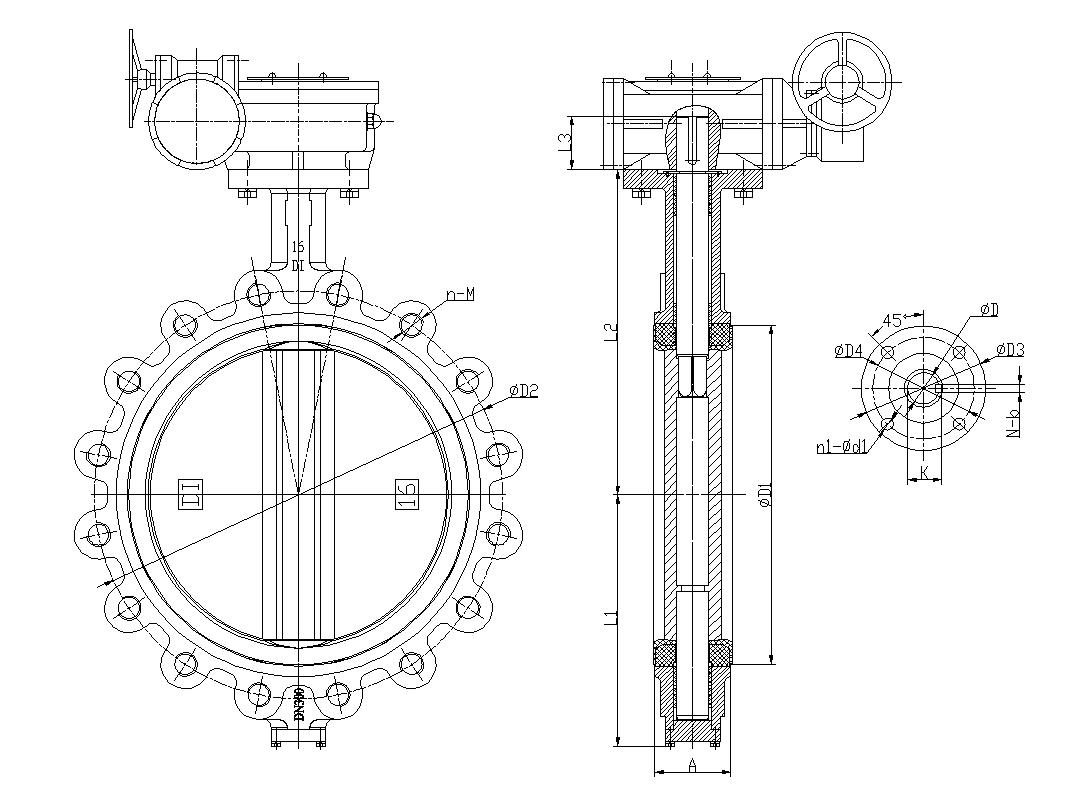

| DN | A | D1 | L1 | L2 | L3 | φD | N-b | K | PN16 | PN10 | 150LB | φD3 | φD4 | n1-φd1 | ||||

| D2 | n-φd | D2 | n-φd | D2 | n-φd | |||||||||||||

| 16″ | DN400 | 86.5 | 436 | 320 | 403 | 52 | 33.15 |

1-10 |

36.2 | 525 | 16-M27 | 515 | 16-M24 | 539.8 | 16-1″ | 175 | 140 |

4-18 |

| 18″ | DN450 | 104.6 | 487 | 351 | 415 | 52 | 38 |

1-10 |

41 | 585 | 20-M27 | 565 | 20-M24 | 577.9 | 16-1 1/8″ | 175 | 140 |

4-18 |

| 20″ | DN500 | 130 | 532 | 386 | 466 | 64 | 41.15 |

1-12 |

44.2 | 650 | 20-M30 | 620 | 20-M24 | 635 | 20-1 1/8″ | 175 | 140 |

4-18 |

| 24″ | DN600 | 152 | 651 | 446 | 525 | 70 | 50.65 |

1-16 |

54.7 | 770 | 20-M33 | 725 | 20-M27 | 749.3 | 20-1 1/4″ | 210 | 165 |

4-22 |