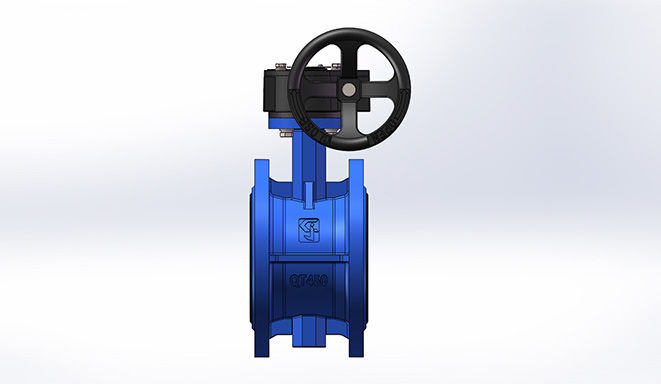

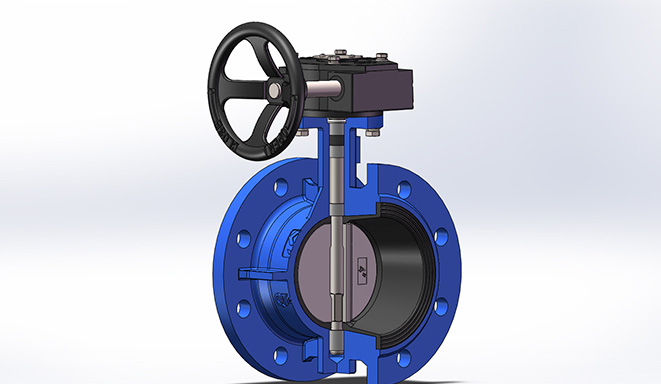

| Design and Manufacture Standard: | API 609 |

| Face to Face:: | API 609 |

| Test Standard: | API 598 |

| Top Flange Connection Standard: | ISO 5211 |

| Flange Size Standard: | ASME B16.5、ASME B16.47、DIN 2501 |

| ASME B16.1、JIS B2220 |

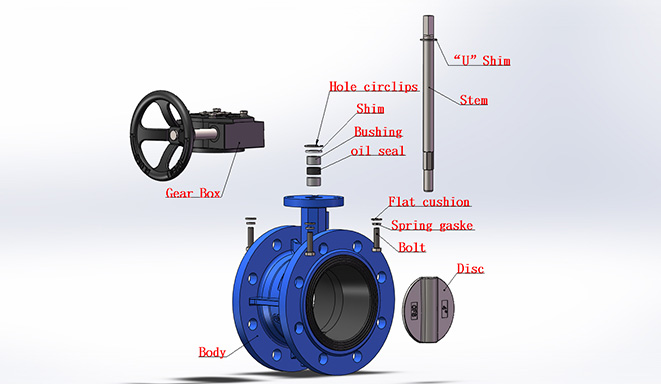

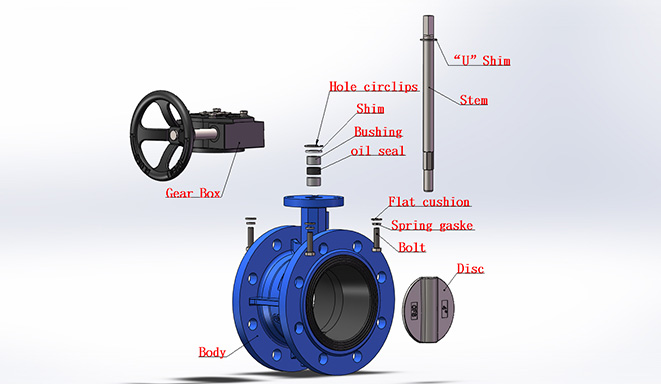

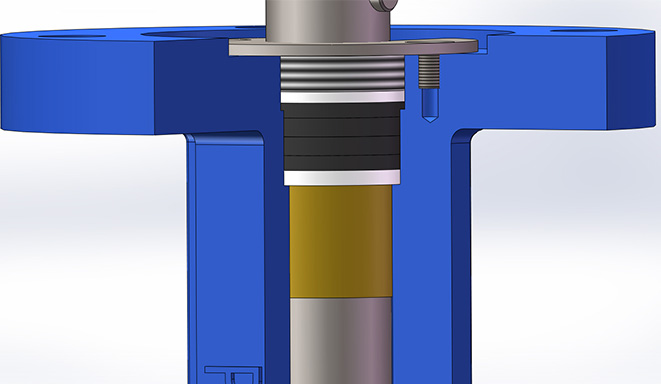

| Body Materials: | DI |

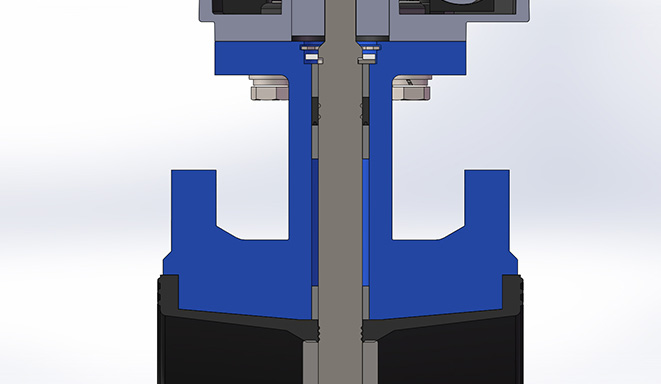

| Disc Materials: | DI、CF8、CF8M、CF3、CF3M、1.4529、C594、C598 |

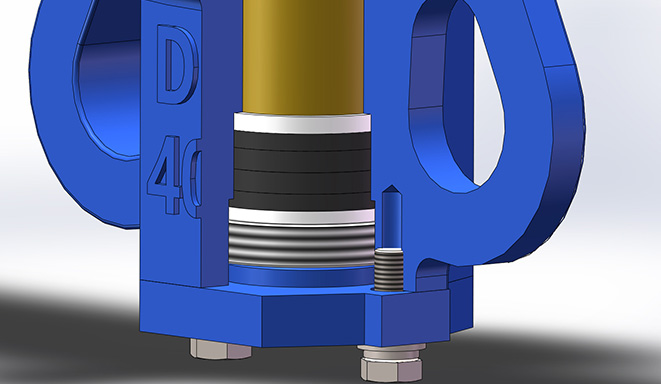

| Seat Materials: | EPDM、NBR、Viton、PTFE |

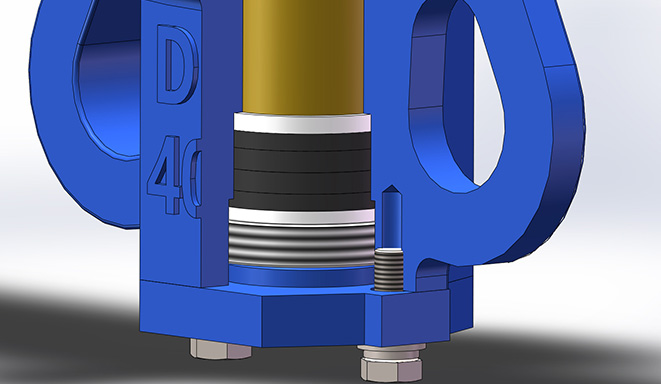

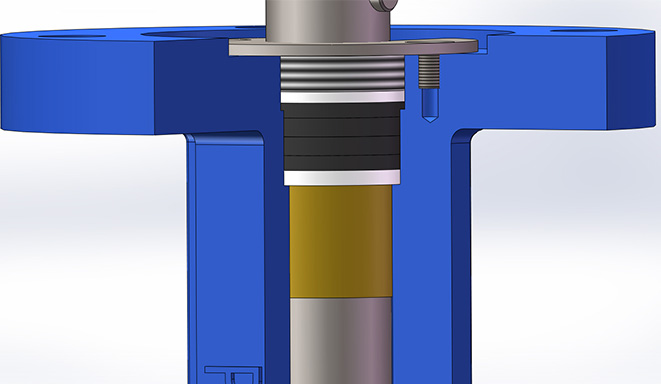

| Stem Materials: | 45、SS416、SS420、SS304、SS431 |

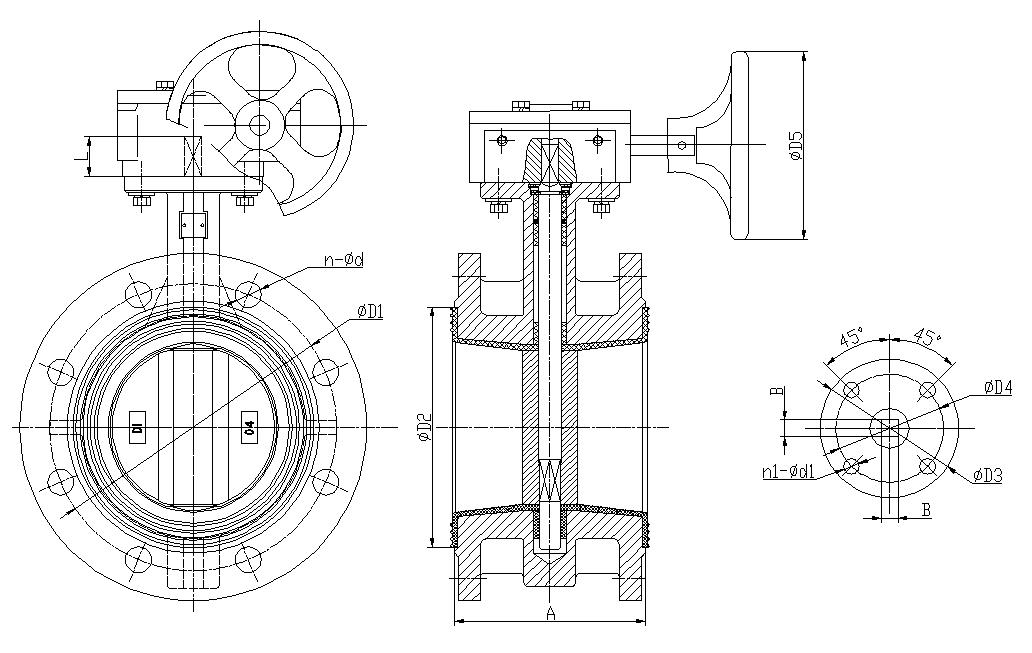

| DN | A | PN16 | PN10 | 150LB | D2 | L | B | φD3 | φD4 | n1-φd1 | φD5 | ||||

| D1 | n-φd | D1 | n-φd | D1 | n-φd | ||||||||||

| 2″ | DN50 | 108 | 125 | 4-19 | 125 | 4-19 | 120.7 | 4-19 | 90 | 25 | 9 | 65 | 50 | 4-8 | 135 |

| 2.5″ | DN65 | 112 | 145 | 4-19 | 145 | 4-19 | 139.7 | 4-19 | 110 | 25 | 9 | 65 | 50 | 4-8 | 135 |

| 3″ | DN80 | 114 | 160 | 8-19 | 160 | 8-19 | 152.4 | 4-19 | 124 | 25 | 9 | 65 | 50 | 4-8 | 135 |

| 4″ | DN100 | 127 | 180 | 8-19 | 180 | 8-19 | 190.5 | 8-19 | 150 | 28 | 11 | 90 | 70 | 4-10 | 135 |

| 5″ | DN125 | 140 | 210 | 8-19 | 210 | 8-19 | 215.9 | 8-22.4 | 176 | 28 | 14 | 90 | 70 | 4-10 | 135 |

| 6″ | DN150 | 140 | 240 | 8-23 | 240 | 8-23 | 241.3 | 8-22.4 | 200 | 28 | 14 | 90 | 70 | 4-10 | 135 |

| 8″ | DN200 | 152 | 295 | 12-23 | 295 | 8-23 | 298.5 | 8-22.4 | 258 | 33 | 17 | 125 | 102 | 4-12 | 270 |

| 10″ | DN250 | 165 | 355 | 12-28 | 350 | 12-23 | 362 | 12-25.4 | 310 | 33 | 22 | 125 | 102 | 4-12 | 270 |

| 12″ | DN300 | 178 | 410 | 12-28 | 400 | 12-23 | 431.8 | 12-25.4 | 362 | 33 | 22 | 125 | 102 | 4-12 | 270 |

| 14″ | DN350 | 190 | 470 | 16-28 | 460 | 16-23 | 476.3 | 12-28.4 | 421 | 45 | 22 | 125 | 102 | 4-12 | 270 |

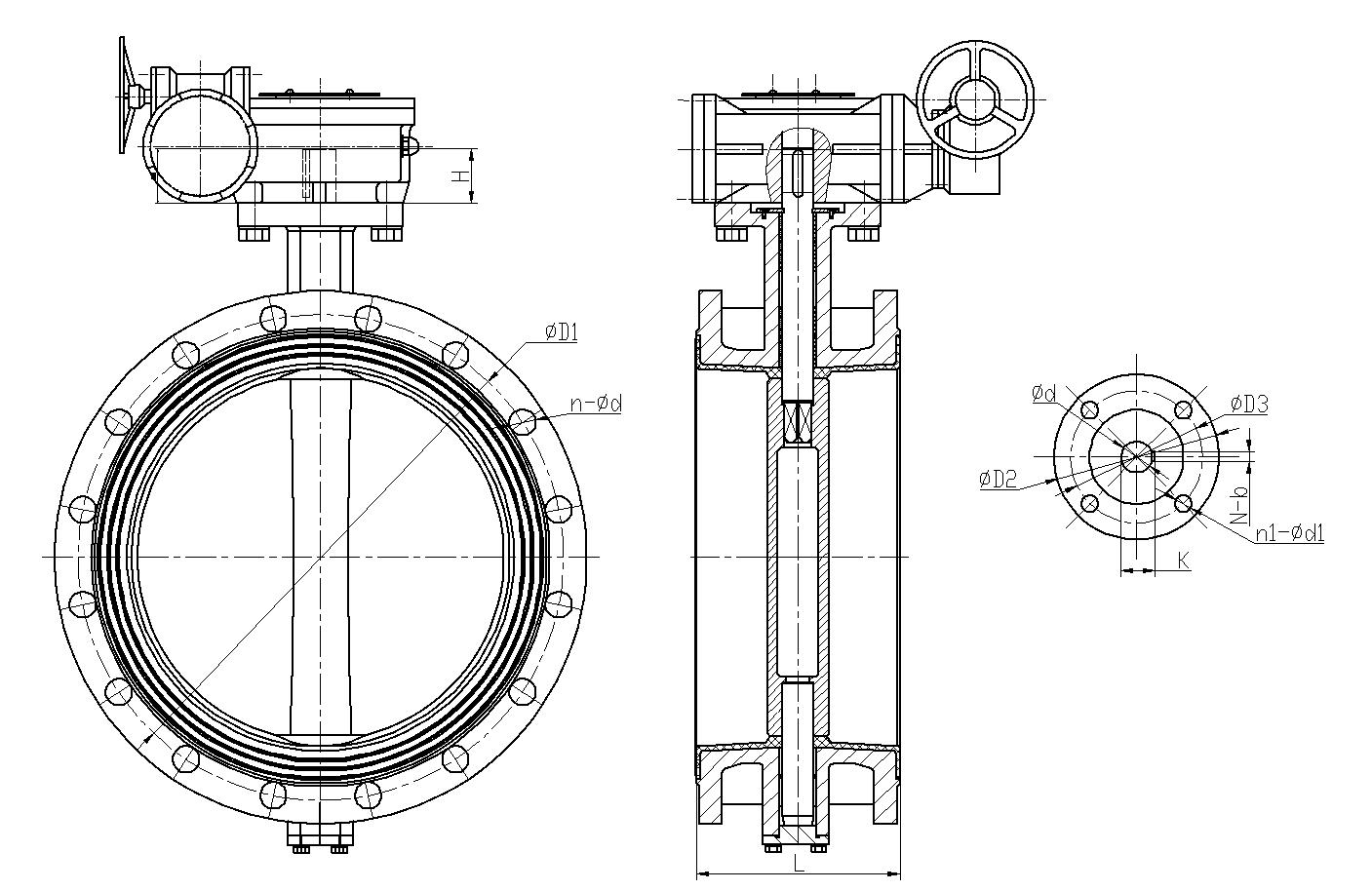

| DN | L | PN16 | PN10 | 150LB | H | φd | K | φD2 | φD3 | n1-φd1 | N-b | ||||

| D1 | n-φd | D1 | n-φd | D1 | n-φd | ||||||||||

| 16″ | DN400 | 216 | 525 | 16-31 | 515 | 16-28 | 539.8 | 16-28.4 | 52 | 33.15 | 36.2 | 175 | 140 | 4-18 | 1-10 |

| 18″ | DN450 | 222 | 585 | 20-31 | 565 | 20-28 | 577.9 | 16-31.8 | 52 | 38 | 41 | 175 | 140 | 4-18 | 1-10 |

| 20″ | DN500 | 229 | 650 | 20-34 | 620 | 20-28 | 635 | 20-31.8 | 64 | 41.15 | 44.2 | 175 | 140 | 4-18 | 1-12 |

| 24″ | DN600 | 267 | 770 | 20-37 | 725 | 20-31 | 749.3 | 20-35.1 | 70 | 50.65 | 54.7 | 210 | 165 | 4-22 | 1-16 |

| 28″ | DN700 | 292 | 840 | 24-37 | 840 | 24-31 | 863.6 | 28-35.1 | 95 | 63.35 | 71.4 | 300 | 254 | 8-18 | 2-18 |

| 32″ | DN800 | 318 | 950 | 24-40 | 950 | 24-34 | 977.9 | 28-41.1 | 95 | 63.35 | 71.4 | 300 | 254 | 8-18 | 2-18 |

| 36″ | DN900 | 330 | 1050 | 28-40 | 1050 | 28-34 | 1085.8 | 32-41.1 | 130 | 75 | 84 | 300 | 254 | 8-18 | 2-20 |

| 40″ | DN1000 | 410 | 1170 | 28-43 | 1160 | 28-37 | 1200.2 | 36-41.1 | 130 | 85 | 95 | 300 | 254 | 8-18 | 2-22 |

| 48″ | DN1200 | 470 | 1390 | 32-49 | 1380 | 32-40 | 1422.4 | 44-41.1 | 150 | 105 | 117 | 350 | 298 | 8-22 | 2-28 |

| 56″ | DN1400 | 530 | 1590 | 36-49 | 1590 | 36-44 | 1651 | 48-47.8 | 200 | 120 | 134 | 415 | 356 | 8-33 | 2-32 |

| 60″ | DN1500 | 570 | 1710 | 36-57 | 1700 | 36-44 | 1759 | 52-47.8 | 200 | 140 | 156 | 415 | 356 | 8-33 | 2-36 |

| 64″ | DN1600 | 600 | 1820 | 40-56 | 1820 | 40-50 | -- | -- | 200 | 140 | 156 | 415 | 365 | 8-33 | 2-36 |

| 72″ | DN1800 | 670 | 2020 | 44-56 | 2020 | 44-50 | 2096 | 60-50.8 | 280 | 160 | 178 | 475 | 406 | 8-40 | 2-40 |

| 80″ | DN2000 | 760 | 2230 | 48-62 | 2230 | 48-50 | -- | -- | 280 | 160 | 178 | 475 | 406 | 8-40 | 2-40 |