Wafer check valve is mainly used at the water supply and drainage pipe network wells or the water pump outlet of fire fighting, petrochemical, light textile, papermaking and high-rise buildings. It is a safety device to prevent the backflow pressure difference of pipeline medium and forming water hammer impact and water pump reversal when the water pump is stopped.

| Design and Manufacture Standard: | API 594 |

| Face to Face | API 594 |

| Test Standard: | API 598 |

| Body Materials: | DI |

| Disc Materials: | DI、CF8、CF8M、CF3、CF3M |

| Seat Materials: | EPDM、NBR |

| Stem Materials: | SS420、SS304 |

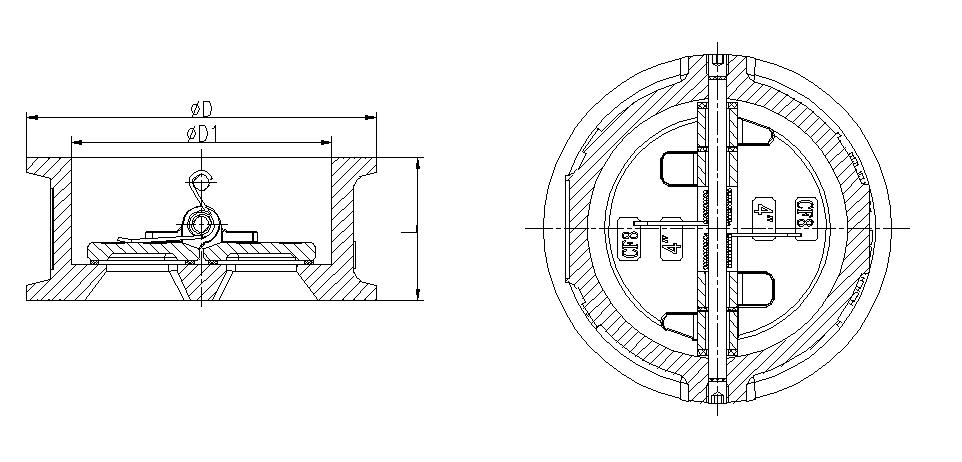

| DN | φD | φD1 | L | DN | φD | φD1 | L | |

| 2″ | DN50 | 101 | 65 | 43 | 12″ | 378 | 310 | 114 |

| 2.5″ | DN65 | 118 | 80 | 46 | 14″ | 438 | 360 | 127 |

| 3″ | DN80 | 132 | 94 | 64 | 16″ | 489 | 410 | 140 |

| 4″ | DN100 | 157 | 117 | 64 | 18″ | 539 | 450 | 152 |

| 5″ | DN125 | 186 | 145 | 70 | 20″ | 594 | 505 | 152 |

| 6″ | DN150 | 213 | 170 | 76 | 24″ | 695 | 624 | 178 |

| 8″ | DN200 | 272 | 224 | 89 | 28″ | 810 | 720 | 229 |

| 10″ | DN250 | 328 | 265 | 114 | 32″ | 917 | 825 | 241 |